Right now we have several used engines for sale

Bespoke Parts Program

We manufacture tailored spare parts for our customers needs.

Our Bespoke Parts Program

Through our tailored gas engine spare parts program, we are able to address the needs of our customers and offer them a highly specific solution.

Many products in our portfolio have been developed in close collaboration with our customers: either in response to known issues or as niche products for particular boundary conditions or requirements.

With our many years of experience and the use of the latest technologies, we can also refurbish certain standard parts to optimize their performance in our customers’ specific applications.

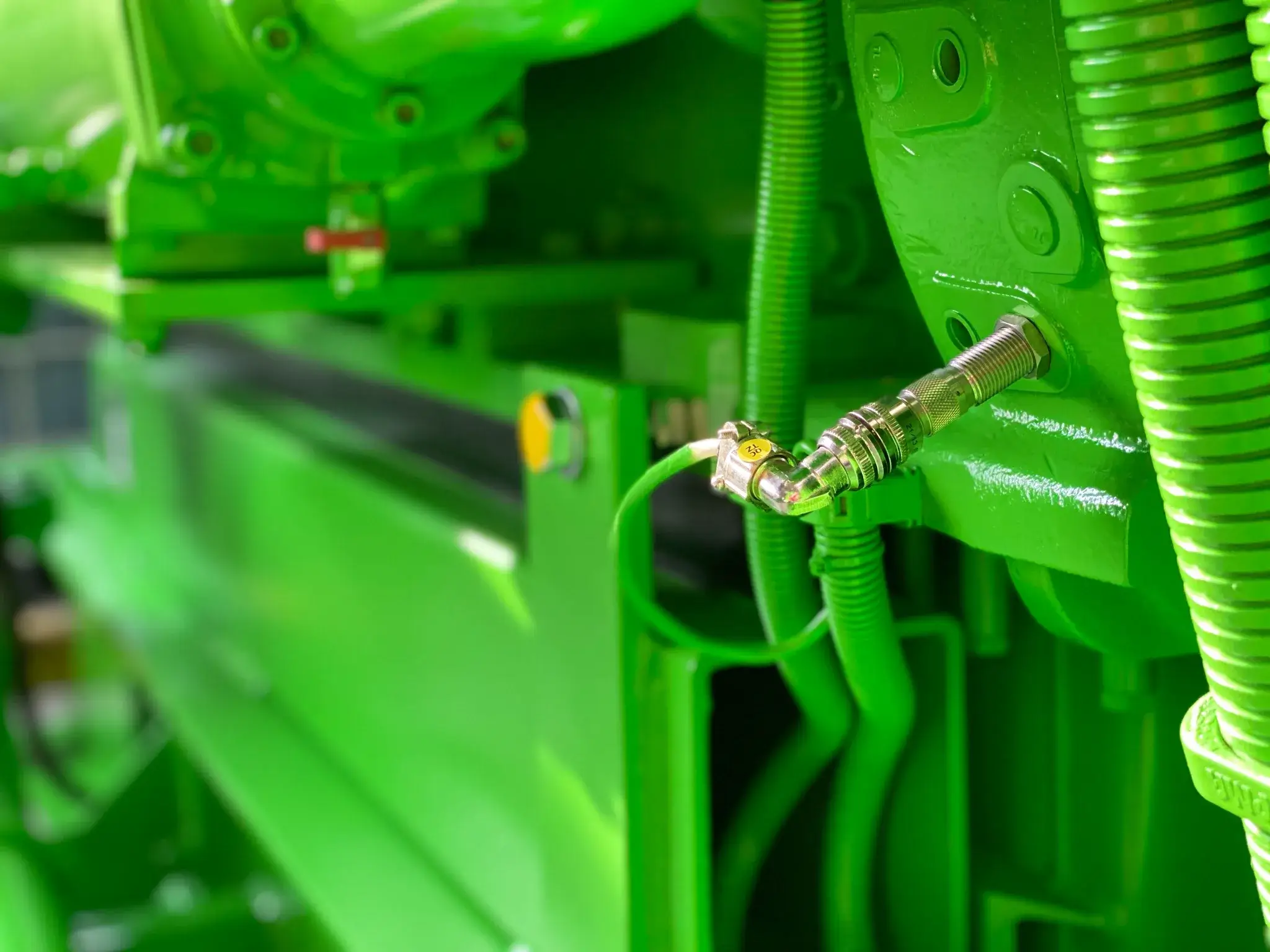

Spare Parts for Gas Engine Services

Timely access to the right spare parts for your gas engine is crucial for maintaining the efficiency and reliability of your biogas plant, generator or gas engine.

Whether you’re in need of parts for a gas engine repair, gas engine overhaul, or a gas engine upgrade for better performance, our inventory is stocked with high-quality, durable gas engine spare parts to meet these needs.

We provide parts for Jenbacher® and MWM® that are specifically designed to ensure compatibility and enhance the functionality of your gas engine.

For Jenbacher® Gas Engines

We offer gas engine spare parts such as pistons, spark plugs or blowby-filter for Jenbacher® Type 3, Type 4 and Type 6 gas engines. Our year-long experience with Jenbacher® allows us to offer parts that promise high quality and durability, ensuring optimal engine performance.

For MWM® Gas Engines

We provide a big range of gas engine spare parts including pistons, spark plugs, cylinder heads and other maintenance parts, suitable for MWM® models TCG 2016, TCG 2020, TCG 3016, and TCG 3020. Due to our independent experience with the MWM® engines, we are able to provide high quality and durability, combined with fast delivery.

Number of different spare parts

0

+

Customer satisfaction

0

%

Blowby gas is a hidden efficiency killer in gas engines. Learn how modern filter solutions protect components, cut oil loss, and reduce service costs—backed by real data.

When gas engines underperform or age, choosing between remanufacturing, rebuilding, or overhauling is crucial. This article explains the differences and highlights how PowerUP’s condition-based overhauls offer targeted, cost-effective solutions to restore engine performance and extend service life.

REMAN engines are emerging as the go-to solution in industries where cost-efficiency and performance are key. Through a detailed remanufacturing process that adheres to OEM standards, these engines offer new-like reliability, extended service life, and a smaller environmental footprint. Especially for operators of gas and biogas engines, REMAN units provide a smart, sustainable alternative to buying new—backed by warranties and built for durability. With PowerUP’s expertise, you can ensure optimal performance and reduced downtime, all while supporting a circular economy.

Remanufactured gas engine spare parts play a big role in efficient maintenance strategies. Discover five compelling advantages of using REMAN components—from cost savings to environmental benefits—especially when paired with condition-based overhauls.

What exactly is REMAN, and how does it differ from rebuilt or overhauled engines or components? In this article, we explain the process of remanufacturing, its benefits, and why REMAN plays a growing role in industrial engine maintenance.

Jenbacher® engines are renowned for their efficiency in converting fuel into energy. They operate on the principle of internal combustion, where a mixture of air and fuel is ignited to produce power.

Learn how these advanced engines transform fuel into power while maintaining high efficiency and low emissions.

Dive into the world of Jenbacher® engine rebuilds and see how these gas engines get a second life. Learn about the steps involved in restoring an engine to peak performance, from disassembly and inspection to reassembly and testing.

Learn about the distinctive attributes, operational efficiency, and sustainability of each series, from the versatile Type 2 and Type 3 to the powerful Type 9. This guide shows how Jenbacher® engines drive innovation in the power generation sector, setting new standards for performance and environment.

This blog post explores the company’s evolution from its modest origins to its status as a global player in providing efficient, sustainable power solutions.

Frequently asked questions to the Bespoke Parts Program

What makes the Bespoke Parts Program unique?

Our Bespoke Parts Program is unique because it offers tailored solutions for biogas and natural gas engines. Many of our products are developed in collaboration with customers, addressing specific issues or requirements. With our experience and latest technologies, we also specialize in refurbishing standard parts to optimize their performance for specific applications.

How does the Bespoke Parts Program ensure compatibility and functionality of parts for specific engines?

We place a strong emphasis on sourcing and providing parts that are suitable for specific engine models, particularly for Jenbacher® and MWM® engines. Our meticulous approach ensures that the functionality of your gas engine is enhanced with parts that perfectly fit and meet operational requirements.

Can PowerUP provide spare parts for both repairs and upgrades of gas engines?

Yes, our inventory is well-stocked with high-quality, durable parts suitable for a range of needs, including gas engine repairs, overhauls, and upgrades. Whether it’s for routine maintenance or performance enhancement, we have the right parts to support your engine’s efficiency and reliability.

How does PowerUP’s experience contribute to the effectiveness of the Bespoke Parts Program?

Our many years of experience in the field allow us to understand the nuanced needs of different gas engines. This expertise, combined with the use of the latest technologies, enables us to not only supply the right parts but also advise on and implement refurbishments and optimizations that benefit our customers’ specific engine applications.