Right now we have several used engines for sale

Gas engine spare parts & products

Our product range for gas engine spare parts, consumables, service solutions and gas engine upgrades

Gas Engine Spare Parts and Control Systems – explore our technology portfolio

PowerUP has a big portfolio of cutting-edge products and gas engine spare parts designed to address the unique challenges faced by our customers in the realm of gas engine applications.

Our expertise lies in the manufacturing of top-quality spare parts for gas engines, along with offering controller solutions for your engine, as well as our own genset PUPGEN.

We cater to a diverse range of suppliers, as well as customized requests tailored to your specific needs.

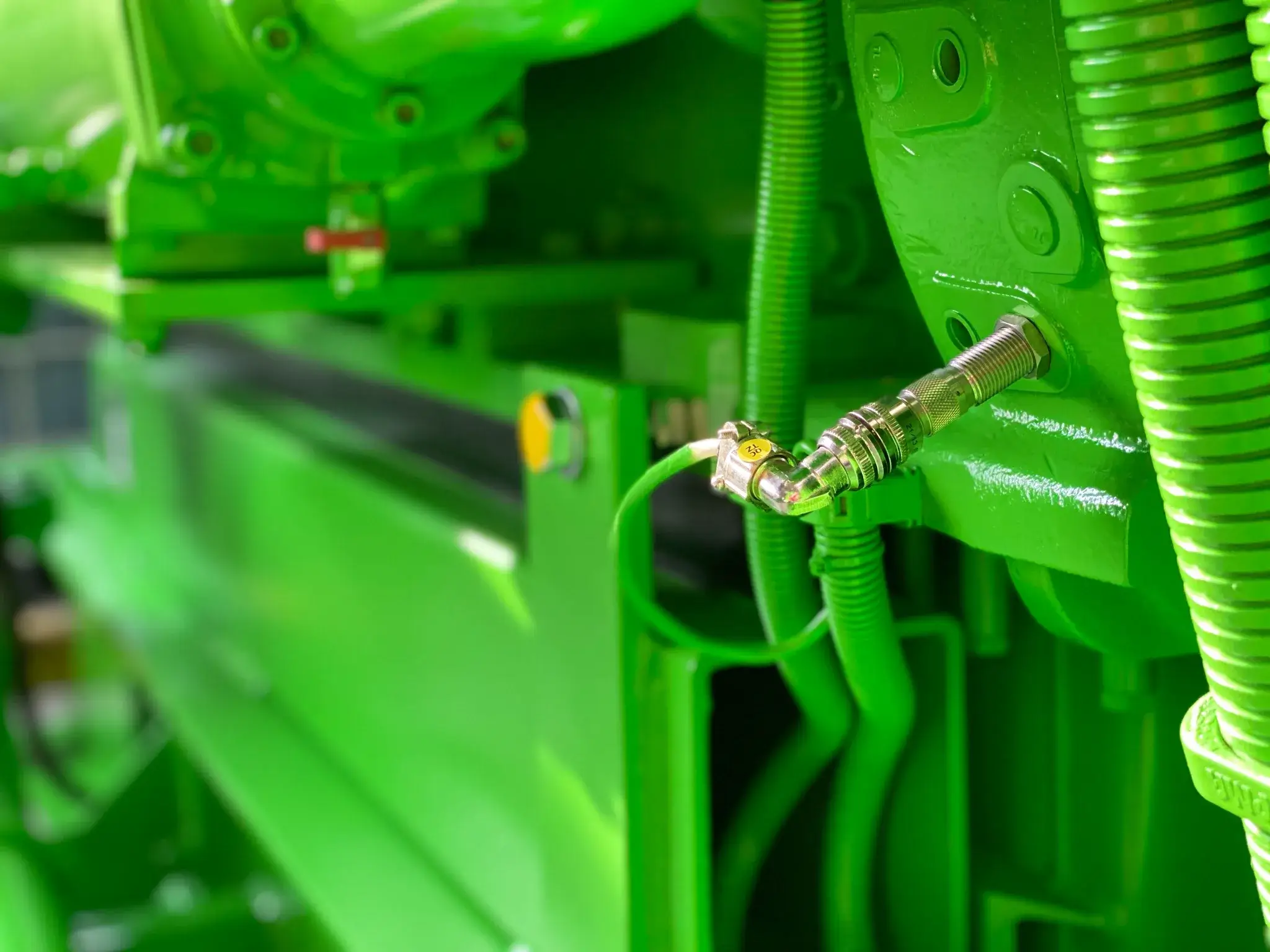

Parts suitable for MWM® Engines

To further establish our position as an international expert in gas engine spare-parts, service-solutions and upgrade-development PowerUP now also offers full services and parts, suitable for MWM® engines.

Jenbacher® Engines

We have years of strong in-house research and development for our Jenbacher® products and our experienced engineers are dedicated to delivering only the best to our customers.

Gas Engine Spare Parts for MWM® and Jenbacher®

We specialize in providing high-quality consumables/expendables, suitable for MWM® and Jenbacher® engines. We stock a wide array of components tailored to models like the TCG 2016 or the Type 6, ensuring compatibility and optimal performance.

Purchase gas engine spare parts directly from PowerUP. Whether for gas engine upgrades or gas engine repair, our experienced team can efficiently guide you to the right parts, helping maintain the efficiency and longevity of your engines.

EDI and AORA — Control Systems for Gas Engines

EDI and AORA control systems for gas engines – operators can achieve a higher level of control and insight into their gas engines, leading to improved performance and reduced operational costs. PowerUP ist specialized in implementing and optimizing these software control systems.

Both systems are equipped with the latest technology that enables seamless integration with existing engine setups, making them suitable for a wide range of gas engine models e.g., Jenbacher® Type 3 or MWM® TCG2016.

EDI and AORA are advanced control systems specifically designed to optimize the performance and efficiency of natural gas engines and biogas engines. These systems provide precise control over engine operations, ensuring optimal fuel efficiency, reduced emissions, and enhanced reliability.

EDI, with its user-friendly interface, allows for real-time monitoring and adjustments for Jenbacher® gas engines, making it ideal for managing complex engine dynamics.

AORA suitable for MWM® gas engines focuses on advanced analytics and predictive maintenance, helping to prevent downtime and extend the life of the engine.

Subscribe to the PowerUP Innovation-Letter

Get the the latest innovations and upgrades regarding gas engines delivered to your inbox each month.

Blowby gas is a hidden efficiency killer in gas engines. Learn how modern filter solutions protect components, cut oil loss, and reduce service costs—backed by real data.

When gas engines underperform or age, choosing between remanufacturing, rebuilding, or overhauling is crucial. This article explains the differences and highlights how PowerUP’s condition-based overhauls offer targeted, cost-effective solutions to restore engine performance and extend service life.

REMAN engines are emerging as the go-to solution in industries where cost-efficiency and performance are key. Through a detailed remanufacturing process that adheres to OEM standards, these engines offer new-like reliability, extended service life, and a smaller environmental footprint. Especially for operators of gas and biogas engines, REMAN units provide a smart, sustainable alternative to buying new—backed by warranties and built for durability. With PowerUP’s expertise, you can ensure optimal performance and reduced downtime, all while supporting a circular economy.

Remanufactured gas engine spare parts play a big role in efficient maintenance strategies. Discover five compelling advantages of using REMAN components—from cost savings to environmental benefits—especially when paired with condition-based overhauls.

What exactly is REMAN, and how does it differ from rebuilt or overhauled engines or components? In this article, we explain the process of remanufacturing, its benefits, and why REMAN plays a growing role in industrial engine maintenance.

Jenbacher® engines are renowned for their efficiency in converting fuel into energy. They operate on the principle of internal combustion, where a mixture of air and fuel is ignited to produce power.

Learn how these advanced engines transform fuel into power while maintaining high efficiency and low emissions.

Dive into the world of Jenbacher® engine rebuilds and see how these gas engines get a second life. Learn about the steps involved in restoring an engine to peak performance, from disassembly and inspection to reassembly and testing.

Learn about the distinctive attributes, operational efficiency, and sustainability of each series, from the versatile Type 2 and Type 3 to the powerful Type 9. This guide shows how Jenbacher® engines drive innovation in the power generation sector, setting new standards for performance and environment.

This blog post explores the company's evolution from its modest origins to its status as a global player in providing efficient, sustainable power solutions.