MWM® gas engines and combined heat and power plants — a perfect combination

CHP plants are one of the key technologies in modern energy generation. MWM® gas engines, developed through decades of technological innovation, are at the core of many of these CHPs. They combine power, efficiency, and sustainability, setting the standard for CHP applications.

An introduction to the technology of Block Heating Power Plants

By efficiently combining electricity and heat generation, CHPs are setting new standards in modern energy supply. They provide high efficiencies and contribute to a sustainable energy pathway.

The basic principle and functioning of combined heat and power plants

Combined heat and power (CHP) plants, also known as cogeneration plants, operate on a simple yet ingenious principle: maximizing energy efficiency by simultaneously producing electricity and useful heat from a single fuel source, typically natural gas.

In a CHP plant utilizing gas engines, the process begins with the combustion of natural gas within the engine to generate mechanical power. This power is then converted into electricity through an alternator or generator.

However, unlike conventional power plants where waste heat is discharged into the environment, CHP plants capture this excess heat produced during electricity generation. This recovered thermal energy is, e.g., utilized for heating purposes, such as providing hot water or steam for industrial processes, space heating, or district heating systems.

By harnessing both electricity and heat from the same fuel source, CHP plants can achieve high efficiency levels. This not only reduces fuel consumption and greenhouse gas emissions but also enhances overall energy sustainability and cost-effectiveness.

Advantages of CHP in modern energy supply

CHP offers several benefits in modern energy supply. Thanks to the principle of cogeneration, combined heat and power plants efficiently utilize primary energy for both electricity and heat generation. This results in high overall energy efficiencies and reduced CO₂ emissions.

Additionally, CHP systems provide decentralized energy production, ensuring flexible energy supply directly at the point of consumption. This minimizes transmission losses and enhances grid stability. Furthermore, CHP systems support the use of renewable gases, contributing to the transition towards sustainable and renewable energy sources.

The significance of gas engines in CHPs

Gas engines play a crucial role in combined heat and power (CHP) plants. They serve as a dependable power source to drive the generator. In comparison to other types of engines, gas engines offer cleaner combustion, reduced emissions, and efficient energy conversion.

Furthermore, the utilization of natural gas or biogas enables a flexible adaptation to diverse energy sources. When combined with cogeneration, gas engines enhance the overall efficiency of CHPs and facilitate sustainable energy generation.

What makes MWM® gas engines stand out?

The history of MWM®, formerly known as Motoren-Werke Mannheim, dates back to the year 1871, when Carl Benz founded the company in Mannheim. Over the decades, MWM has evolved into a leading provider of propulsion systems for the energy industry.

The pioneering work in the field of gas engines is particularly noteworthy. Through continuous innovation and a strong focus on quality and efficiency, MWM® has become a notable partner for combined heat and power plants worldwide.

Gas engines by MWM® are designed not only to run effectively, but also on low operational and service costs, which adds to their efficiency. Furthermore, they are flexible, as they can be fuelled by different gas sources, including natural gas, landfill gas and biogas.

The story of MWM® – A journey through innovation and progress

Founded by none other than Carl Benz, MWM® has undergone an impressive development since its establishment. Continue reading to learn more!

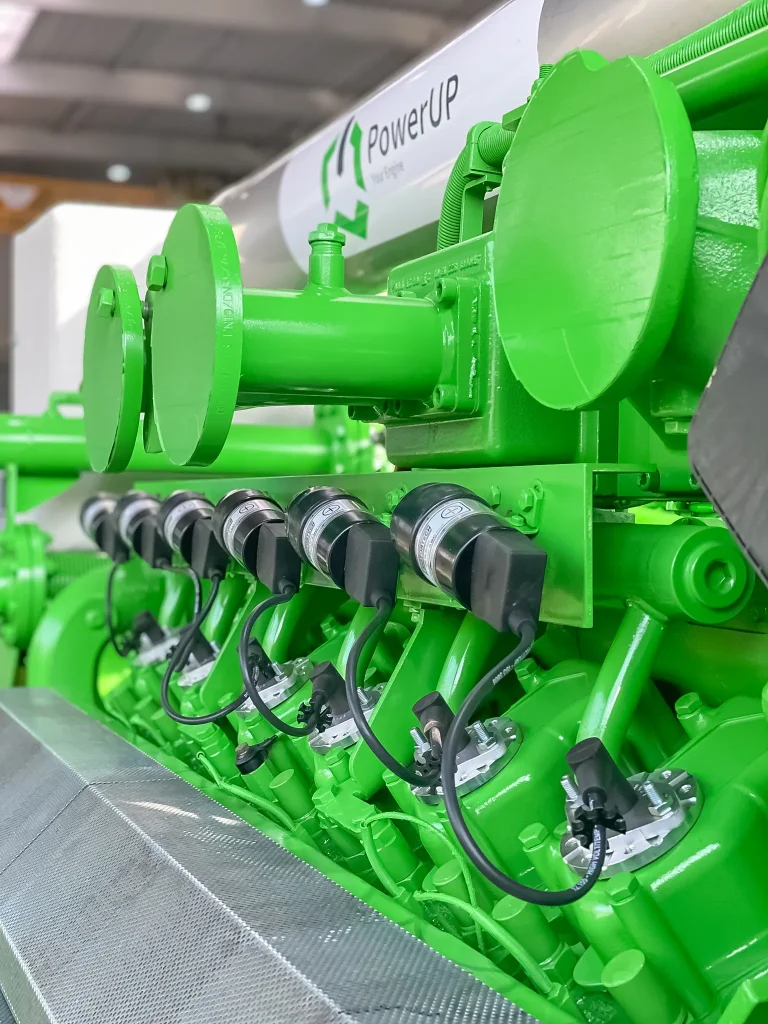

Introducing PowerUP and our core competencies

As PowerUP, an innovative company from Tyrol, we have established ourselves as a leading manufacturer of gas engine spare parts. Furthermore, PowerUP provides specialized gas engine services aimed at maximizing the lifespan and efficiency of gas engines.

With profound technical expertise, state-of-the-art manufacturing technology, and a customer-centric approach, we establish benchmarks in terms of quality and reliability.

High-quality spare parts for enhanced efficiency

The efficiency and longevity of gas engines also depend significantly on the quality of their spare parts. High-quality gas engine parts not only ensure optimal performance, but also reduce downtime and maintenance costs.

They minimize wear, extend the intervals between service calls, and protect the engine from premature failure. In an industry where reliability and uptime are crucial, high-quality spare parts can make the difference between efficient operation and costly breakdowns.

PowerUP specializes in using partially custom-made spare parts to ensure optimal performance and reliability. Moreover, we can aid in making your engine even more efficient and durable – e.g. with an upgrade of the engine control system that allows us to offer remote monitoring and support.

Our product range includes

- cylinder heads

- cylinder liners with anti-polishing ring

- blowby filters

- pistons and spark plugs

- different maintenance parts

Service offerings and support by PowerUP for MWM® gas engines

PowerUP provides a wide range of service offerings and support for engines like MWM® gas engines. In addition to high-quality spare parts, our services include gas engine repair and upgrades, condition based overhaul, gas engine remote service and field service.

Trends and developments in CHP technology

The CHP technology is currently undergoing significant advancements. One trend is the increasing utilization of renewable gases like biomethane, which contributes to an improved CO₂ balance. Furthermore, digitalization is gaining importance: intelligent control systems optimize operation and facilitate remote monitoring.

The modularity of the systems enables a flexible adaptation to various energy needs. In addition, efforts are being made to develop more compact units that reduce space requirements. These advancements hold the promise of more efficient and sustainable CHP solutions for the future.