Versatile Power – The Range of Gases for Jenbacher® Gas Engines

This article explores how these engines adapt to different fuels, from natural gas to biogas and beyond, showcasing their flexibility and efficiency. Let’s uncover the secret behind Jenbacher® engines’ compatibility with various gases, making them a cornerstone of sustainable and adaptable energy solutions.

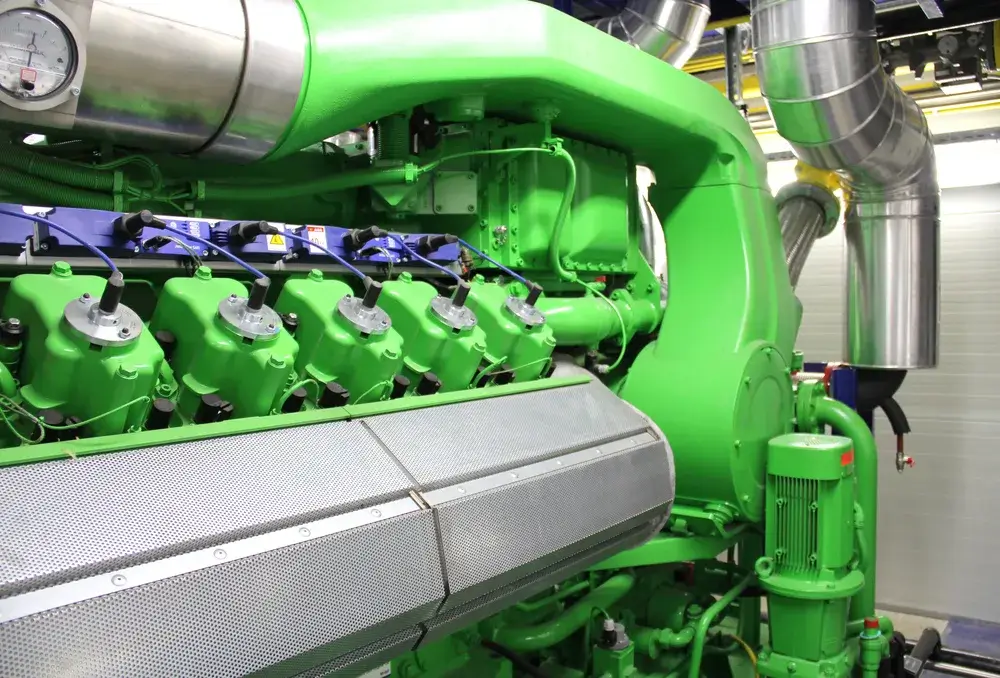

Introduction to Jenbacher Gas Engines

Known for their exceptional efficiency and versatility, Jenbacher® gas engines can operate on a wide spectrum of gases, making them suitable for a vast range of applications, from industrial cogeneration to renewable energy projects. A big plus of Jenbacher® engines is their ability to deliver sustainable, high-performance power solutions, catering to the ever-evolving energy needs of industries worldwide.

Natural Gas – The Primary Fuel

Natural gas serves as the primary fuel for Jenbacher® gas engines, due to its widespread availability and relatively low environmental impact. As a clean-burning fossil fuel, natural gas significantly reduces emissions of pollutants and greenhouse gases when compared to coal and oil, aligning with global efforts to mitigate climate change.

Biogas – Renewable Energy Source

Biogas, a renewable energy source produced through the anaerobic digestion of organic materials, represents a key fuel option for Jenbacher® gas engines. Utilizing biogas not only supports waste management strategies but also contributes to the reduction of greenhouse gas emissions, promoting circular economy principles. Jenbacher® engines adeptly convert biogas into electricity and heat, offering a sustainable solution for farms, wastewater treatment plants, and landfills, thus playing a crucial role in the global shift towards renewable energy sources.

Landfill Gas – Turning Waste to Power

Landfill gas, a byproduct of the decomposition of organic waste in landfills, is another alternative fuel for Jenbacher® gas engines, turning waste management challenges into valuable power generation opportunities. Capturing and utilizing landfill gas not only prevents methane, a potent greenhouse gas, from entering the atmosphere but also provides a renewable energy source that reduces reliance on fossil fuels.

Hydrogen and Hydrogen Blends – Future of Clean Energy

Hydrogen and hydrogen blends represent the frontier of clean energy for Jenbacher® gas engines, offering a glimpse into a future powered by zero-emission fuels. As the energy sector moves towards decarbonization, hydrogen stands out for its potential to supply clean, sustainable power. Jenbacher engines are being adapted to utilize hydrogen, overcoming technical challenges to harness this promising energy carrier.

Special Gases – Beyond Conventional Fuels

Jenbacher® gas engines exhibit remarkable flexibility, extending beyond conventional fuels to operate on a variety of special gases, including flare gas, syngas, and more. This adaptability allows Jenbacher® engines to tap into less conventional energy sources, turning otherwise wasted resources into valuable power and heat. The ability to utilize such a broad array of gases not only demonstrates the engines’ technical versatility but also aligns with the broader goal of maximizing resource efficiency and reducing environmental impact.

Frequently asked questions

How does the use of hydrogen affect gas engine performance?

Hydrogen, being a zero-carbon fuel, can significantly reduce the carbon footprint of power generation when used in gas engines. These engines are designed to adapt to the unique properties of hydrogen, including its high flame speed and low energy density compared to natural gas.

Modifications and control strategies are implemented to manage these differences, ensuring that the engine operates efficiently and safely. While the use of hydrogen may require adjustments in engine design and operation, it opens up new possibilities for achieving high efficiency and drastically lowering emissions, marking a promising direction for sustainable energy solutions.

What makes Jenbacher® engines suitable for a variety of gas types?

Several factors contribute to their suitability for a wide range of gas types. Firstly, Jenbacher® engines are equipped with sophisticated fuel injection and combustion control systems that can be adjusted to accommodate different gas compositions, ensuring optimal performance.

Additionally, the engines are designed with materials and components that can withstand the corrosive properties of various gases, such as biogas and landfill gas. This adaptability allows Jenbacher® engines to efficiently convert diverse gas types into reliable electricity and heat, making them a versatile choice for multiple applications across the energy sector.

What is the price for a Jenbacher® gas engine?

The price of a Jenbacher® gas engine varies widely depending on the model, specifications, and configuration. Costs can range significantly, reflecting the engine’s size, power output, and any customized features or technologies included. For accurate pricing and further information, it’s recommended to contact a sales representative from INNIO® or an authorized distributor like PowerUP.