How does combined heat and power (CHP) work?

Combined heat and power (CHP) is an efficient and environmentally friendly method of energy generation that simultaneously produces both electrical energy and heat. This technology not only contributes to the reduction of CO₂ emissions but also significantly enhances energy efficiency.

In this article, we will delve into the fundamentals of CHP and explore how it functions. With over 10 years of experience, we are an expert in the gas engine industry – offering gas engine spare parts, services like condition based overhaul or gas engine upgrades, and other tailored solutions.

What is cogeneration?

Combined heat and power (CHP), also known as a CHP plant or CHP system, is an energy generation process where the heat produced during electricity generation is not wasted, but instead used efficiently. This process can be employed in different facilities such as power plants, industrial installations, or residential buildings. The primary objective of CHP is to utilize the waste heat generated during electricity production for heating buildings, industrial processes, or for the provision of hot water.

How does combined heat and power (CHP) work?

The functioning of combined heat and power (CHP) is based on the principle of simultaneously generating electricity and heat. While there are various technologies and plant concepts that can be used for CHP, the fundamental process remains similar:

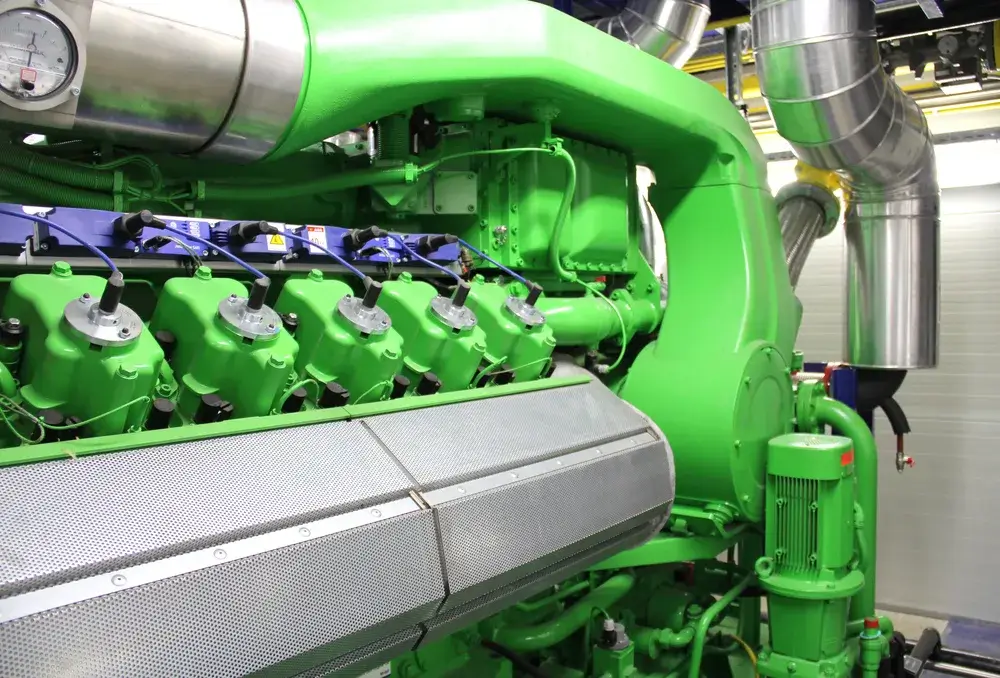

Internal combustion engines or gas turbines

In many CHP plants, internal combustion engines or gas turbines are used. These engines burn fossil fuels such as natural gas or diesel. During the combustion process, not only is mechanical energy generated to drive a generator for electricity production, but waste heat is also produced. This waste heat can be utilized for heating purposes or other industrial processes.

Steam turbines

In some cogeneration systems, steam turbines are utilized. In this process, the fuel is burned to generate steam, which then drives a turbine, enabling the generator to produce electricity. The hot steam that exits the turbine still retains a significant amount of thermal energy, which is harnessed in heat exchangers to heat water or generate steam for heating purposes.

Advantages of cogeneration

By simultaneously producing electricity and heat and making efficient use of waste heat, cogeneration contributes to optimizing energy consumption and minimizing environmental impact. In the following, we will explore some of the central advantages of this innovative method of energy generation

Energy independence

CHP systems, especially those that utilize renewable fuels like biogas or biomass, can contribute to the reduction of dependency on external energy sources. This is particularly significant in regions or countries that heavily rely on energy imports

The local generation of electricity and heat through CHP plants enables greater energy independence and contributes to strengthening energy security.

Decentralized energy generation

The power-heat-coupling allows for the decentralized production of energy. This means that energy is generated directly at the point of consumption, whether in industrial facilities, commercial areas, or residential areas

This reduces energy losses caused by long transmission paths, resulting in higher efficiency. Decentralized CHP systems can also contribute to the stabilization of the power grid, particularly during times of high demand or shortages.

Reduced grid load

When CHP systems are utilized in industrial facilities or residential buildings, they have the capability to generate the necessary electricity on site, thereby reducing the burden on the public power grid. This can result in improved load distribution and a more stable power supply overall.

Economic advantages

CHP systems can also provide economic advantages. By reducing energy costs and having the ability to feed surplus electricity back into the grid, operators of CHP plants can generate additional income. In several countries, there are government incentives and support programs in place to promote the adoption of CHP systems, making investments more appealing.

Drawbacks of Combined Heat and Power (CHP)

Despite its numerous advantages, cogeneration also comes with certain challenges and drawbacks:

Complexity and investment costs

The implementation of cogeneration systems often requires a substantial investment in technology and infrastructure. The acquisition and installation of necessary equipment, such as engines, turbines, and heat exchangers, can be expensive

This can be particularly challenging for smaller businesses or buildings. The complex nature of CHP technologies also necessitates specialized expertise in design, installation, and operation, which requires additional training and resources.

Dependency on fuels

The majority of CHP systems rely on fossil fuels such as natural gas or diesel for energy generation. This dependence on limited and environmentally harmful resources exists, despite the increased efficiency of CHP compared to conventional separate electricity and heat production. Consequently, the use of fossil fuels in CHP systems contributes to greenhouse gas emissions

The transition to renewable energy sources and advanced fuels can alleviate this issue, but it often necessitates additional technological advancements.

Matching electricity and heat demands

When the heat demand in a CHP system is low, there can be an imbalance between the heat generated and the electricity generated. In such cases, the excess heat may need to be disposed of or additional electricity may be required to maintain the system’s balance. Accurate planning and control are necessary to ensure optimal operating conditions.

Combined heat and power and biogas

The combination of combined heat and power (CHP) with biogas as a fuel offers intriguing opportunities in the realm of sustainable energy generation. Biogas is produced through the anaerobic fermentation of organic materials such as biomass or agricultural waste. This process yields methane gas, known as biogas, which can be utilized as a renewable energy source

In CHP plants, biogas can be utilized in combustion engines or gas turbines to generate both electricity and heat. This provides the dual advantage of enhancing energy efficiency and utilizing renewable resources.

Biogas combined heat and power (CHP) systems offer several advantages. Firstly, biogas utilizes organic waste that would otherwise potentially be disposed of in landfills and converts it into energy. This helps to reduce waste and mitigate methane emissions from decomposing waste, thereby contributing to waste reduction and environmental sustainability

Secondly, biogas is a renewable fuel that, in comparison to fossil fuels, has a lower CO₂ footprint. Therefore, the combination of biogas and CHP technology can contribute to further minimizing the environmental impact of energy generation.

What does PowerUP do?

With a range of gas engine solutions, PowerUP provides you with service and spare parts suitable for brands like INNIO Jenbacher®, MWM® and Caterpillar®. From specially designed gas engine spare parts to gas engine repairs, replacement engine, and even a container solution – thanks to our expertise in this field, our customers always benefit from the highest quality service.